GUIDE TO FRAMING NAILS

When starting a new framing project whether its new construction or remodeling work it is important to pay attention to very important details. There are many important details that can commonly be overlooked when getting lost in the big picture of the building plans, layouts, design or any constraints that we have to consider when building. One of the most important but smallest of details we like to consider in our work involves carefully considering what nail is going to be most suitable for the building application we are dealing with that day. In this blog we will explore the different kinds of nails available on the market for wood framing and how my team and I decide what nails to use on the job site, as well as which ones are generally good to always have on hand to cover a wide variety of building demands.

Nail Sizing

Before we delve into the types of nails it is important we gauge what size nails we need.The most commonly used sizes for framing nails are 16d and 10d. Below is a chart that breaks down the lengths of the nails 16d being 3 ½ inches long and 10d being 3 inches long. When attaching half inch sheathing 8d(2 ½”) and 6d(2”) is commonly used. On the packaging of the nails you will commonly see a number like .092 or .131 next to your length dimension, this measurement is the thickness of the nail, for heavy duty or structural use you will generally use thicker nails. It is always recommended to consult with an architect or engineer to determine the necessary nail dimensions to comply with local building codes.

Nail types

In new construction or remodeling work, there are several types of nails available on the market for framing. When deciding what nail to use, keep some of these factors in mind; specific application, the type of wood being used, and the desired structural integrity. Here are some commonly used nails and their benefits in different building stages:

Common Nails: Common nails are the most basic and widely used nails in wood framing. They have a smooth shank and a flat head. These nails are suitable for general framing purposes, including attaching studs, plates, and joists. Their benefits include:

Versatility: Common nails can be used in various wood framing applications.

Cost-effective: They are relatively inexpensive and readily available.

Box Nails: Box nails are similar to common nails but have a thinner shank. They are commonly used for light framing, sheathing, and other applications where the wood may split easily. Their benefits include:

Reduced splitting: The thinner shank decreases the chances of splitting the wood.

Neater appearance: Box nails leave smaller holes in the wood due to their thinner shank.

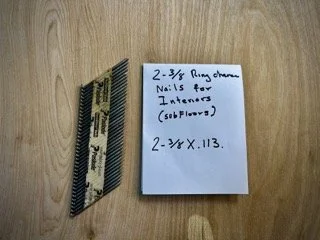

Ring-Shank Nails: Ring-shank nails have rings along the shank that provide increased holding power. These nails are beneficial in structural applications where stronger connections are required. Their benefits include:

Enhanced grip: The rings along the shank create friction, making them resistant to withdrawal.

Improved structural stability: The increased holding power of ring-shank nails helps prevent loosening over time.

Spiral-Shank Nails: Spiral-shank nails have a twisted or spiral pattern along the shank. This design enhances their holding power and resistance to withdrawal. They are commonly used in shear walls, decking, and other structural applications. Their benefits include:

Superior holding power: The spiral pattern provides excellent grip and minimizes the chances of nail pull-out.

Increased resistance to withdrawal: Spiral-shank nails are less prone to loosening under load or movement.

Joist Hanger Nails: Joist hanger nails are specifically designed for attaching joist hangers and other metal connectors to wood. They have a short length and a large, flat head. Their benefits include:

Precise size: Joist hanger nails are engineered to fit the holes of joist hangers, ensuring proper installation.

Secure connections: The large head helps prevent the metal connectors from slipping or shifting.

These are just some of the common examples of nails used for framing. Another feature that can set these nails apart is the availability of different nail coatings, metal types and manufacturing processes. We listed a few with some of the benefits of their unique composition for certain projects.

NAIL COATING TYPES

Stainless Steel Coating: Stainless steel coated nails are highly corrosion-resistant and suitable for both indoor and outdoor applications. They are particularly beneficial in environments with high moisture content or exposure to chemicals. Stainless steel nails are durable and maintain their integrity over time, making them a popular choice in construction, marine, and coastal applications.

Polymer Coating: Polymer-coated nails have a layer of polymer or resin applied to the surface of the nail. This coating provides several advantages, including improved corrosion resistance, increased holding power, and reduced friction during installation. Polymer-coated nails are commonly used in treated lumber, decking, siding, and other exterior applications.

Cement Coating: Cement-coated nails have a thin layer of cement or other adhesive material applied to the shank. This coating enhances the holding power and grip of the nail in concrete or masonry applications. Cement-coated nails are commonly used for attaching furring strips, wood blocking, or framing members to concrete or masonry surfaces.

Epoxy Coating: Epoxy-coated nails feature a layer of epoxy resin applied to the nail's surface. This coating provides corrosion resistance, enhances holding power, and helps prevent moisture penetration. Epoxy-coated nails are often used in pressure-treated lumber, decking, trim, and other exterior applications.

Heat Treatment: Some nails undergo a heat treatment process to increase their strength and hardness. Heat-treated nails are less likely to bend or break during installation, providing better durability and holding power. They are commonly used in applications where high structural integrity is required, such as heavy framing, timber construction, or load-bearing installations.

Hot Dipped Galvanized or zinc plated nails: They are both coated in zinc but the manufacturing process is different although the benefits are generally the same. Zinc plated nails electroplating is done by the process of electro deposition. The fasteners are dipped in a chemical bath containing dissolved zinc. When direct electric current is applied, the zinc metal at the anode begins to dissolve, and the free metal ions reach the cathode to form a thin layer of zinc coating on the fastener. Hot dip galvanizing, is the process of dipping fabricated steel into a kettle or vat containing molten zinc. Here are some of the many shared benefits of the zinc coating:

Corrosion Resistance: Galvanized or zinc-coated nails are treated with a layer of zinc that provides corrosion resistance. This feature is particularly beneficial in outdoor or high-moisture environments where regular nails may be susceptible to rusting. The corrosion resistance helps to maintain the structural integrity and longevity of the nail, reducing the risk of failure over time.

Extended Lifespan: The zinc coating or galvanizing process enhances the durability of the nails, extending their lifespan compared to regular nails. This feature is especially important in applications where long-term performance and stability are essential, such as framing, decking, or exterior trim work.

Improved Holding Power: The zinc coating or galvanizing process adds a slightly thicker layer to the nails, resulting in increased diameter or weight. This increased size provides improved holding power and better resistance to withdrawal, making them suitable for structural applications where strong connections are required.

Compatibility with Pressure-Treated Wood: Pressure-treated wood contains chemicals that can corrode regular steel nails over time. The corrosion-resistant properties of galvanized or zinc-coated nails make them compatible with pressure-treated lumber, ensuring long-lasting and secure connections.

Versatility: Galvanized or zinc-coated nails are available in various types and sizes, making them suitable for a wide range of applications. Whether it's framing, sheathing, decking, or siding, these nails can be used in both interior and exterior projects, providing versatility in construction and remodeling work.

Of the listed nail types we found that these are some of the most superior nails to consider using for their high quality.

Hot-Dipped Galvanized Nails: Hot-dipped galvanized nails are highly recommended for new construction framing. These nails undergo a process where they are immersed in molten zinc, providing a thick, durable coating that offers excellent corrosion resistance. Hot-dipped galvanized nails are suitable for both interior and exterior applications and provide long-lasting performance, especially in areas prone to moisture or harsh weather conditions.

Stainless Steel Nails: Stainless steel nails are another popular choice for new construction framing, particularly in coastal areas or environments with high humidity or exposure to chemicals. Stainless steel nails offer superior corrosion resistance, making them highly durable and ideal for long-lasting connections. They are compatible with various types of wood and are suitable for both interior and exterior framing applications.

Ring-Shank or Spiral-Shank Nails: For enhanced holding power and improved structural stability, ring-shank or spiral-shank nails are often considered superior options for new construction framing. These nails have special features that increase their grip and resistance to withdrawal. The rings or spiral pattern along the shank of these nails create friction and help prevent loosening over time, ensuring strong and secure connections.

It's important to note that the selection of nails should be based on local building codes, industry standards, and the specific requirements of your project.

We use just about every nail there is in the variety of work we do

Be sure to look for our future blog where we discuss the nailers available on the market for using these nail types in the most efficient way.